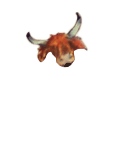

Roses are red… sausages are square ❤️

Turn a classic Scottish favourite into a quirky Valentine’s treat!

Heart-shaped Lorne, pork link sausage, waffles, beans and melted cheese all baked into one ultimate Love Sausage Pie.

Would your Valentine love this? 👀

Thanks to the support around our January initiatives (Puddin Race & Sideburns) and a contribution from the business, we are delighted to announce that we donated £5,000 to SAMH in January.

What do you get when you mix running shoes, a good dose of Scottish spirit, and a whole lot of haggis? An unforgettable day — that’s what.

Our recent Simon Howie 5k Puddin’ Race and Fun Run brought together runners, families, friends, and plenty of familiar faces for a day that celebrated fitness, fun, and community — with a Simon Howie twist, of course.

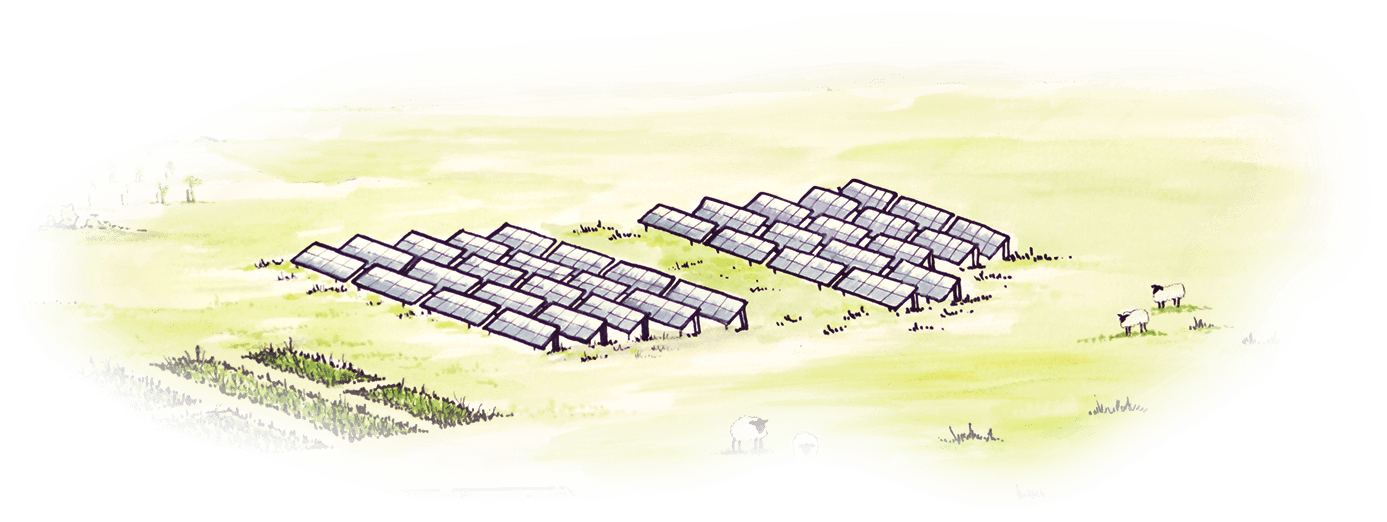

The UK’s best-selling haggis and the only haggis to go to the edge of space!

2 star winner, Great Taste 2022 – Haggis worthy of the occasion!

Explore Articles

Explore Articles

Click & Collect

Click & Collect